| Thin-film technology is harnessed to create the recording transducers on silicon wafers, which are then cut into individual sliders. The sliders are then mounted on the suspension / arm assembly into the HDDs. As a leading provider of advanced magnetic recording heads for HDDs, we have contributed extensively in reducing the head and assembly size while increasing head's recording density. These advancements will eventually enable HDDs to store tens of tera-bytes of data in 95mm diameter of recording medium. |

| Advanced Product Development and Manufacturing Technologies |  | ||

| Our technology teams are in constant pursuit of innovation and new designs to increase the recording density of magnetic recording heads. Our manufacturing teams utilize Artificial Intelligence algorithms and automation to create ever smarter-factories that minimizes human errors and improve operational efficiencies. | |||

| ||

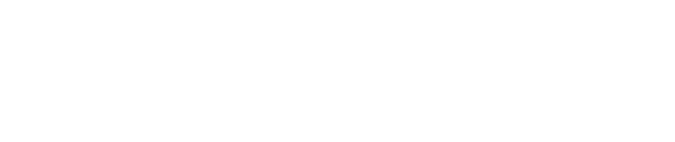

| Slider Fabrication | ||

| Slider fabrication is the process of parting a wafer containing tens of thousands of recording transducers into a form factor called slider, with each slider embodying one recording transducer. A finished slider is called a head. The flying height, or the gap between the slider and the magnetic medium during a recording/reading operation, of less than 10 nano-meters means we have to use the most advanced micro-machining and vacuum technologies to deliver the extreme mechanical specifications required in the sliders. | ||

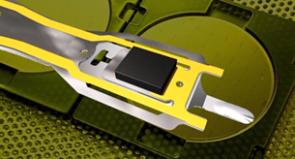

| Ultra-Precision Assembly |  | ||

| The technology of recording heads does not end with sliders. The sliders need to be mounted on a suspension into so called Head Gimbal Assembly (HGA) and Head Stack Assembly (HSA) in order to be integrated into HDDs. These assemblies require ultra-precise wire bonding and attachment processes, while making sure they are debris-free. The technological sophistication of these sub-assemblies, in conjunction with the constant process updates has made developing their corresponding production lines an extreme engineering challenge. Many of the production equipment required in our manufacturing lines are so unique that SAE develops and fabricates most of our production equipment ourselves. | |||

| ||||||||